Combi Combing Aprons

Performance & Versatility

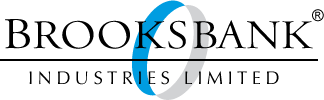

Developed specifically for use on the latest NSC PB33, ERA and Sant’ Andrea P100 and Millennium machines. Excellent results are also obtained on all earlier NSC and Sant’ Andrea models of combing machines.

Recommended for combing the following fibres:

- Merino Wool of all microns

- Wool/Synthetic blends

- 100% Synthetics

- Mohair

- plus many other fibres and fibre blends

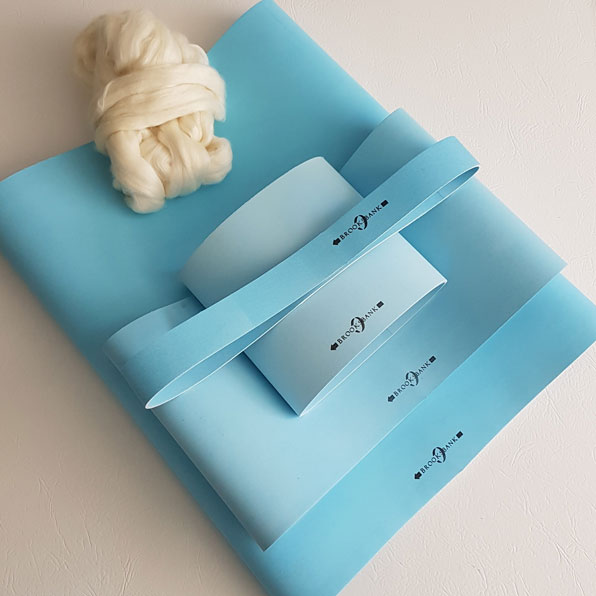

Standard Combi Apron Sizes: 640 x 530mm, 580 x 540mm & 580 x 520mm.

Any size of apron can be manufactured for all combing machines.

Combi aprons give an excellent performance when fitted on:

The advantages of using the combi combing apron

The advantages of using the Brooksbank Combi Synthetic Combing Apron over Polyurethane combing aprons

- The Combi Combing Apron has a softer and more accommodating structure than any polyurethane apron. This allows the Combi to conform to the fluting of the drawing off rollers. This results in an extremely efficient drawing off of the sliver, leading to maximum yield and throughput being obtained as well as the Top being of the highest quality.

- Better fibre cohesion is achieved on the surface of the Combi apron, ensuring the fibres remain more parallel than when using a polyurethane apron. With the polyurethane apron there is a tendency for some of the fibres near the edge of the apron to float above the surface of the apron leading to a more uneven straightness of fibres within the Top.

- The soft structure of the Combi apron also helps protect the natural crimp within the wool.

Combi aprons are easier to compress than polyurethane aprons. Even with increased pressure on the drawing off cylinder polyurethane aprons exhibit poorer drawing off and the long non drawn off fibres are taken by the circular comb and end in the noil. By using Combi aprons fewer long fibres end in the noil, therefore the yield is higher and the wastage less. - Combi aprons operate efficiently at much lower combing machine tension and pressure settings than polyurethane aprons. The Combi operates best at the minimum tension settings (as adjusted on either side of the apron) and a lower pressure setting on the drawing off roller of 85mm as opposed to 80mm with a polyurethane apron.

- Because a standard Combi (640 x 530) weighs 700gms as opposed to 1191gms for an average polyurethane apron the same size, shipping costs will be less.

- Being absorbent, Combi aprons also absorb any excess combing oils/lubricants and dirt which might otherwise contaminate the wool Top. With a polyurethane apron this excess material sometimes has to be cleaned off the surface of the apron manually.

- Combi aprons are also considerably less noisy in operation on the combing machine than polyurethane aprons.

N.B. Because of all the above factors and because Combi will give a long and productive life if set up & run correctly on the machine (** see Brooksbank operating suggestions for Combi). N. Schlumberger and Sant Andrea both recommend Combi Synthetic Combing Aprons for use on their new machines the ‘ERA’ and ‘Millennium’. NSC and Sant’ Andrea do not recommend using polyurethane aprons.

Enquiry & Contact Form

Station Yard, Elslack, Skipton, North Yorkshire BD23 3AS, England

Tel: +44 (0)1282 444610

E-mail: sales@brooksbank.com

Registered in England & Wales: Reg. No. 1365964

VAT No. 303454786